Electricity industry is a basic industry and all other industries and activities are directly and indirectly are relative to it. So investing on it is necessary. Countries provide their needed energy from different ways such as fossil, atomic, water, natural gas, coal, and geothermal fuels. From whole of useful used energy, some part of it will be converted to useful energy and a part of it will be wasted. From aspect of producing the electricity hydropower, plants are divided to:

- High head small hydro power plants as a general high head hydro

power plants are cheaper than the low head ones, due to the used turbines.

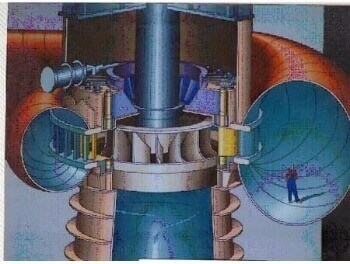

In large hydro power plants the installation place of turbine is on dam installations, water conducts toward turbine by a canal and turns the runner that is connected to turbines shaft and turning the shaft generates electricity.

Hydropower Plants Department and Factory Equipment:

Based on our country's developing policies and localizing the basic industry technology, departments’ goals are de fined in forms of GC and EPC. Based on our 20 years of experiences from abroad training courses and using our unique equipment, the department and company has capabilities in making power plant precise parts, planning, finance and industrial consultant commerce, making engineering, erection, commissioning and project management in manufacturing hydro power plants, Francis, Kaplan and butterfly valves.

Based on our policy, AzarAb has done the engineering construction or left the manufacturing of karun1, Karun2, Karun3, Karun4 or Masjed Soleiman, karkheh power plant and factories equipment to other regional companies and by distributing the work among the regional companies has performed a significant role.

In addition to active participating in domestic industries, this department has been present in international markets such as China, Austria, and Belarus.

In addition, this department has made much effort on continuing the establishment of Occupation Health and Safety Management System OHSAS 18001.

Non-destructive test on all under process parts takes place in hydro power plants and factory equipment department based on most modern methods.

The tests performance guide starts from entering the raw material to our Raw Material Receipt Department by using VT, DT, and UT tests.

In forming unit, metal sheets up to 220mm thickness will be rolled and pipes up to 52" diameter will be bent, performing DT, VT, PT, and VT tests.

In assembling line, precise parts will be assembled in X, Y, Z coordinates and by using digital precise measuring and calibrated tools (Camera and control by machine).

In machining workshop, light and heavy parts up to 200 ton with 12m length, 5m width, 12m diameter, and 6m height are being work with using DT test with hecto-millimeter tolerance.

In welding field based on ASTM, ASME, DIN and other international standards along with VT, DT, PT, MT, UT and RT tests, the qualified methods are being used.

On thermal operation, based on our capability and factory powerful thermal operation equipment, this department issues the stress – relief, aniline and return guides, and regarding the operation has quiet assessment through by Quality Control Department.

Following the first, second and third schedule of the country's economical development, AzarAb has a noteworthy role in the national goals by participating in manufacturing the essential machinery and equipments of mother industries.

Client's satisfaction by on time doing the order and standard quality and least expenses in compare with foreign manufacturer is one this industries company long term schedules.

All attempts and tries of the management and staff would be widely offered to reach to these objectives.

Based on our capabilities and obtained experiences during participating in performing the country's heavy projects and regarding the market potential and current fortunes and threats, market's quality and quantity development, AzarAb has started manufacturing of Francis type hydro turbines equipment from 1985 as follow:

1- Karun 1 hydro-turbine in four units with 250MW power output

2- Karun 3 hydro-turbine in eight units with 250MW power output

3- Karkheh hydro-turbine in three units with 133MW power output

4- Masjed Soleiman hydropower in four units with 250MW Power output

5- Masjed Soleiman developing plan hydropower in four units with 250MW power output

6- Gotvand hydro-turbine in four units with 250MW power output

7- Karun 4 hydro-turbine in four units with 250MW power output

8- Siah Bishe hydro-turbine in four units with 250MW power output

9- Seimare hydro-turbines in three units with 163MW power output

Manufacturing of high capacity hydro-turbines is performed for the first time in Iran. AzarAb in cooperation with FARAB Company based on its strong professional potential both in software and hardware capabilities could solve all problems and difficulties and now produces the high quality products. For instance, the molding of heavy equipments was one of the main problems in the way of these projects and fortunately, now we have successfully solved all of these problems with the help and cooperation of AzarAb's experts.

We offer our thanks to Mr. Mahnama and Mr. Karbalai current managing directors of FARAB and AzarAb companies for their wide attempts and also Mr. Haj Rasoulian the chairman of the board of FARAB for his guidance.

By choosing 30 direct contractors and 50 indirect contractors in the fields of molding and forging under the AzarAb monitoring the manufacturing operation of the project started to perform. After the confirmation of plans and documents by employer agents some portion of the equipment were sent to site and installed. According the most experts' comments, these equipments in compare with the foreign ones have better quality.

Now four units of Masjed Soleiman developing plan, Karun 4, Gotvand and Siah Bishe hydro-turbines equipment manufacturing process have come to conclude with VOITH from Austria, and Seimare project with ALSTOM from France, in which main part of equipment is delivered to VOITH's agency in the least possible time and manufacturing of the rest equipment is still continued.

Draft tube elbow from Seimare hydro-turbine project is delivered to ALSTOM too.

AzarAb has confirmed about 60-milliard Rials investment in water projects, has performed about 90% of the project, and now is generating electricity.

In addition to hardware investment, AzarAb has seriously followed the technology transfer and has made a contract with L.M.Z, in which the first phase of the contract for planning and manufacturing of butterfly valves has successfully ended. In any way AzarAb activity in hydropower plants field focuses on two parts:

1. Planning and manufacturing of butterfly valves

2- Planning and manufacturing of hydro-turbines

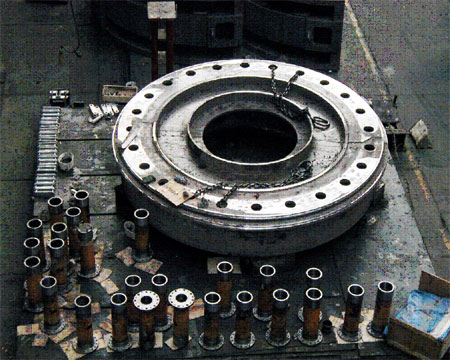

Butterfly Valves:

Butterfly valves is used to open and close the inter water main direction, which includes four main parts as case, disk, upper and lower pipes and two hydraulic jacks. Its diameter and weight is about 5.3m and 272t, which is from the biggest ones in all over the world and just a few countries are able to manufacture it.

Its case weighs about 70t and each one of molded parts is about 11~15t,with about 800mm thickness.

Used sheets thickness is from approximately 30mm to 130mm the its joints are performed with usage of very modern technology and its manufacturing process involves cutting, welding, thermal operation, precise machining, hydrostatic test, leakage test, and system operation test. Regarding its huge dimension, some special equipment is installed in AzarAb. Now the operation of molding, construct, machining, hydrostatic test, and leakage test is successfully ended and we are witness of its operation in hydro power plants.

Hydro-Turbines:

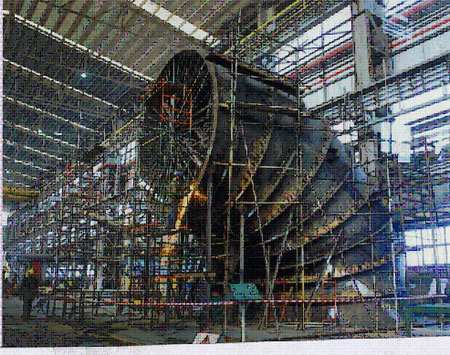

Spiral Case:

Its main duty is to distribute the inlet fluid equally to stay ring in a way that inlet fluid speed is stable to prevent the chock of fluid movement non-symmetry. Geometrical shape of spiral case is like a spiral and the curve causes to reduce the fluid pressure loss to its smallest amount. The spiral case weighs about 170 tons and is made of high-resistance steel alloy sheets (62 U, S460N, P355) with 24 to 60mm thickness.

Due to its curve and non-symmetric it is formed by special rolling operation that needs high technical knowledge and experience and joint to each other by welding operation. Then its complete pre-montage –regarding the dimension control and planning data approval- is perform and tested under 34.8bar water.

Since manufacturing of spiral case parts regarding the algebraic form and high precise need much sensitivity, so RT and UT tests will test all welded directions according the standard.

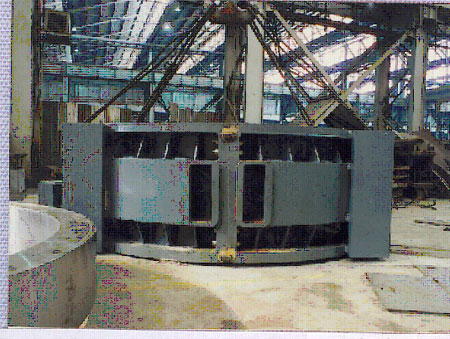

Distributor:

Its main duty is conducting the inlet water to runner blades and a dynamic assembly. This assembly consists of near five thousands small and big parts and are in mechanical conformity with each other, which are mode of antirust martenziti steel which is used in industrial process such as molding, cutting, welding, machining and thermal operation according the international standards and weight about 160 ton.

Distributors move by two hydraulic jacks with 40bar pressure, which is manufactured in AzarAb.

AzarAb Company is now based on its scientific knowledge is among the world's famous companies such as VOITH, ALSTOM, H.E.C, and GE.

Wicket Gate:

Wicket gate plays an important role in hydropower plants. Wicket gate increases turbine revolution and after paralleling with net, increases the turbine load. Changing in turning place of this part causes the change in flow rate of turbine runner. Wicket gate conducts the water flow into runner. In this case, the angle of entering water to runner is too important and plays an important role in efficiency and reducing cavitations.

ecause of nature of flowing water in turbine direction, sandy parcels and impure material, and cavitations causes friction and corrosion in wicket gates. So after a time depend on the condition of operation and the water and grease material, the journal place and the sealing on the wicket will corrode.

In this case, manufacturing and and/or purchasing a new wicket gate is too expensive and needs much time, so AzarAb tries to use certain economical maintenance methods and makes the start to power plants easy.

Based on following applicable method wicket gates can be ready to perform in a short time: total wicket gate cleaning, quality control in all levels repairing the ruined parts, cleaning the welding surfaces, thermal operation for stress – relief, make the repaired surfaces to standard sizes by lathe operation, doing chrome campsite coating in friction surfaces and wicket gates seats.

The machining operation of wicket gate is too important in a way that shaft and seat angle of the sealing should be in the same direction.

Runner:

Runners change the fluid motion moment and make the generator to turn. Since the static pressure of the runner blades is equal, so the pressure does nothing.

The aerodynamic shape of the blades is so that the pressure turns to kinetic energy along the blade so the static pressure in blades both sides are equal. Thus, the static pressure in blades outlet is less than its inlet.

As the turbine is Francis type, the radical inlet flow and in the

The fluid flow on the blades should be symmetrical, to prevent the chock on turbine shaft.

Runner is one of the basic turbine parts so blades should be resistant against cast frictional stresses and cavitations. Its main parts such as blades, crowns, bands are made of antirust steel and in molding method.

Welding these stainless steel parts needs special technology and equipment in which AzarAb is equipped with the best ones. Regarding their dynamically, special sensitive and care is applied in their manufacturing process.

Draft Tube Elbow:

Since the outlet flow contains kinetic energy and the pressure in runner outlet is too low to prevent cavitations and energy loss a make use of unloading pipe is essential that its aerodynamic shape is acquired by the model and dimensional analysis.

Each unloading pipe consists of 16 semi cone segments and weighs 78 tons, which is manufactured by rolling and welding operations with essential technical knowledge and experience.

Servomotor:

To open and close the butterfly valves and turbine moveable blades for regulating the inlet water to runner, two 40 and 60 bar hydraulic jacks are used. As the open and closing time should in a special period, the precise of manufacturing is too high. For example, the inner side of the cylinder should be sangzani to be assured of essential surface safi. In addition, the hydrostatic, leakage, and performance tests for controlling the process of the manufacturing, resistance, and planning verification would be performed.