AzarAb Quality Assurance department, consisting of skilled and experienced personnel (more than 22 years of experience) plays a significant role in different projects. The department controls the quality of products of the company’s basic processes for the conformity of them with requirements of Production Manufacturing Standard, Quality Management System ISO 9001, Environmental Management ISO 14001, and Safety and Occupation Health System OHSAS 18001, with below mentioned titles:

1. Quality Assurance

2. Inspections

3. Nondestructive Tests

4. Central Laboratory

5. Facilities

6. Welder Welding Operator Qualification

Quality Assurance:

This section of Quality Assurance Affairs undertakes the systematic and managerial duties. In this regard, the Quality Management System version 1994 has established in AzarAb in the year 1997. It was confirmed by 2000 version in the year 2003. In addition, Environmental Management System ISO 14001 version 1996 established at 2004 that was confirmed with version 2004 at the year 2005. Meanwhile, by use of the managerial and expertise capabilities along with allocating current expenses and time AzarAb is going to establish OHSAS (Safety and Occupation Health Management System) that will be established in the company in near future. Each of the established Managerial Systems helps AzarAb managerial system and all interested parties to know about the knowledge of process quality and environmental operation and make decisions that are more accurate. For this purpose, we make quantitative evaluation of the results of the basic processes operation and announce their capabilities in monthly reports.

Further, monitoring and measuring the mentioned processes operation provide it to determine their weak and strong point, and to take managerial decisions that are more accurate.

Related to environmental activity the provincial organs such as Environmental Protection Organization, and Water and Sewage Organization are of organizations that should be assured of AzarAb activity correspondence with determined essentials. In this order, some independent organs prepare the documented reports of AzarAb basic processes operation results annually and send them for Environmental Protection Organization. In addition, by proving the conformity between AzarAb activities and environmental requirements, AzarAb fulfills its responsibility against society and people and manufacturing high quality products.

AzarAb personnel try their best to follow occupation health and safety principles under Taking environmental and quality responsibilities. We under take preventing Environmental pollution in one hand, and keeping the safety and occupation health Responsibilities by observing quality standards in other hand. Our basic processes should not have any risks for personnel. Fulfilling these fact current risks have been recognized and evaluated. For reducing and controlling the risks, maintain safety and Occupation health programs in order to obtain our demands.

By making a contract of consultant with Velosi and their foreign expert (an American Mechanical engineering association member) for manufacturing products like boilers and pressuring vessels based on ASME international standard, AzarAb tried to revise and change its production system. For the purpose, we dispose numerous different training courses in purchase planning, welding, quality control, etc., and a 16-revision period during three years based on ASME standard resulting to win the prize at the end.

Inspections:

Most significant inspections used in our production processes for corresponding between final products and products standard requirements and customer specifications such as STM, ASME, AWS, API, ANSI, DIN, JIS, BS and EN are as per followings:

1. Raw material inspection for correspondence between POS standard specifications with related project specifications and raw material specifications with raw material quality certificate

2. Parts making process inspection such as cutting, rolling, bending, beveling and printing the raw material specifications on the parts and so on

3. Fit up and assembling inspection: to be assured of correspondence between products with making maps

4. Welding process inspection: for assuring of following all essential WPS and PQR parameters approved for the project

5. Pneumatic test inspection

6. Leak test inspection

7. Hydrostatic inspection

8. Products erection inspection

9. Paint, sandblast and galvanizing inspection such as viscosity, thickness, impact, and pinhole test

10. Manufacture Data Reports (MDR) and Final Book Inspection

Non-destructive Tests:

Common non-destructive tests are as follow is performing in AzarAb by qualified person certified with written practice according SNT-TC-1A). In addition, number of NDT certified personnel in various test methods are listed below:

| Test Method Level | RT III | RT II | RT I | UT III | UT II | UT I | MT III | MT II | MT I | PT III | PT II | PT I |

| Number of Personnel | 2 | 7 | 8 | 2 | 8 | 5 | 2 | 10 | 5 | 2 | 10 | 8 |

1) Visual Test (VT):

We perform it in all production processes and normally VT should be done before sending products to next process.

2) Radiography Test (RT):

We perform it by use of gamma ray (co60, Ir192) and X-Ray (up to 6Mev). Owning three concrete halls that are certified by Iranian Atomic Energy Organization, we are able to do radiography test in three working phases for the products with 7.5m diameter, near 30-meter length and 380mm thickness using Fine grain films.

3) Ultra Sonic Test (UT):

We perform it by use analog and digital ultra sonic flaw detection devices, angle, normal and TR probes and special probes too. We are able to do ultra sonic tests for all industrial projects. Upon the variety of our products, we are much experienced in this field and in making source test blocks that are different in shape, dimension and material too.

4) Magnetic Particle Test (MT):

We use it according to our product methods such as Yoke, Prod, and Coid, in AzarAb regarding the project requirements. A variety of magnetic materials such as florescent black ink material and dried paint powder are being use of too.

5) Liquid Particle Test (PT):

Washable with solvent or water dye per meant liquids are used in this method, but we are able to make use of other kinds of this process too.

6) NDE Personnel Qualification:

All NDE trained personnel with 10 years of experience are certified by level not personnel, based on written practice and SNT-TC-1A recommendations.

Central Laboratory:

This department of Quality Assurance consists of mechanic, metal orgy, chemistry and calibration laboratories.

1) Mechanic Laboratory:

Test such as traction, bending, impact, sclerometery, thickness gauging, surface smoothing, fracture, flattering, flaring and shear test are being used for raw material, welded joints and parts, and has the experiencing DIN, ASTM, ASME, EN, JIS and GB Standards.

2) Metallurgy and Chemistry Laboratories:

Steel metalography and non-metal alloys along with their result analysis, metal and non-metal alloys, brand determination, samples thermal operation

The operation involve stress relief normalizing temper with electric furnace up to 1200 degree, water analysis, and liquid electric conductivity measurement, corrosion test in weight method, de-acidification and steel metal sloping is the tests being done in metallurgy and chemical laboratories.

3)Calibration Laboratory:

Calibrating all kinds of dimension measuring tools such as caliper, Micrometer, indicator gauge, cylinder gauge, right angle gauge, metal ruler, tape meter, level, Pantometer, Radiometer, standard block, Centro-meter, pedometer, filler gauge, torque-meter and Go not Go gauge

Electric, pressure and temperature tools such as pressure gauges, frequency-meter, oscilloscope, power supply, voltmeter, ampere-meter, speedometer, multi-meter, grab ampere-meters, temperature controllers, thermocouples, paint thickness gauge, weights, hygrometer, mercury, thermometers, calibration

Note: all devices of calibration laboratory are traceable by international standards

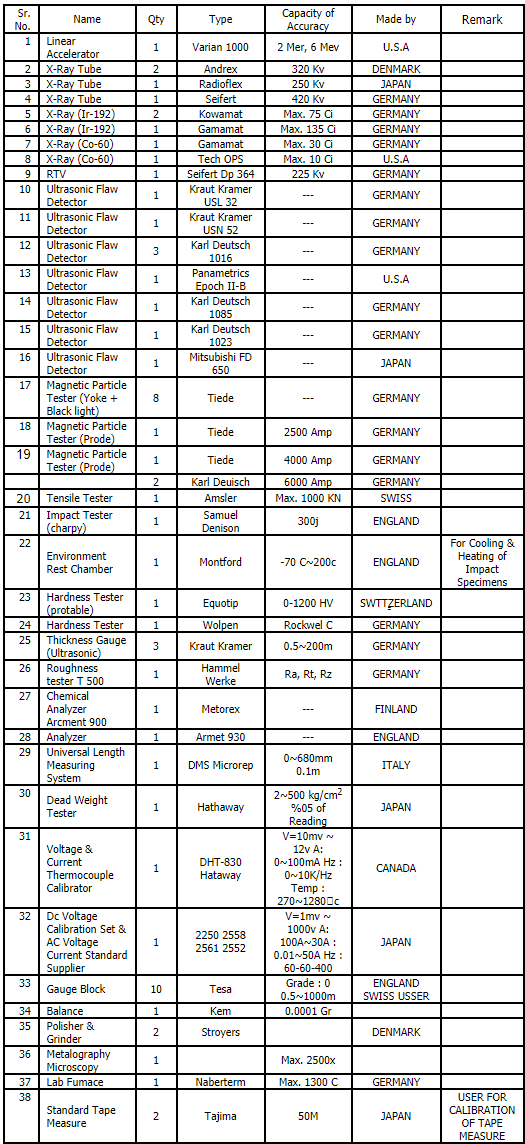

Facilities:

All test equipment (laboratory and shops) is listed as bellow:

List of Test Equipment (Laboratory & Shops)

Welders Qualification

All welders and welding operators in and out of the factory are qualified based on ASME SEC, IX standard and or our customer-modified standard. Those welders who pass the test based on RT and VT and mechanical tests too will take the certificate these certificates will be updated every six-month. The used welding methods for qualifying the welders of GTAW, GMAW, SAW, SMAW and SW in which up to now 1000 welders have been qualified.